1

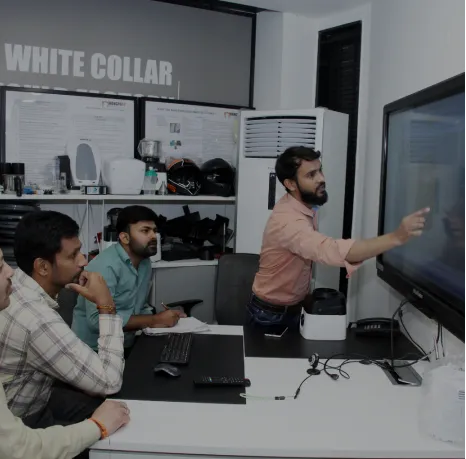

ENGAGEMENT

- The Client contacts us with his product and the challenges.

- We suggest a Face to Face meeting at our office to understand the product and the market.

- We discuss the complete product development and go to market journey to understand the gaps.

2

ALIGNMENT

- This is a No obligation meeting which means you have full control on the process, deliverables and cost.

Let Client to have an experience to explore to see an opportunity of value addition in his Product and Business. - Let Client to have an experience to explore to see an opportunity of value addition in his Product and Business.

3

PROPOSAL & KICK OFF

- In case if you see an opportunity of working together, we offer you a commercial proposal to project kick off.

Team starts working on the project with a committed time lines for product launch. - Team starts working on the project with a committed time lines for product launch.

- Propose the parallel activities to work on

4

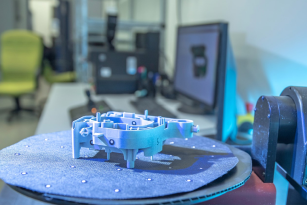

IDEATION & ENGINEERING

- Market Research Understanding the Gaps, Product Ideation concept Design - CTQ Frame work.

- Tooling Development & Production product validation.

- Installation & Batch Production

5

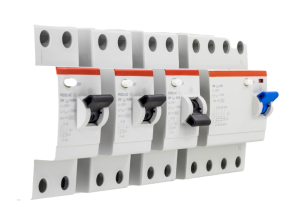

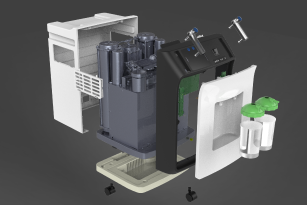

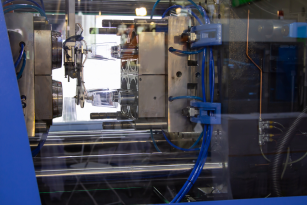

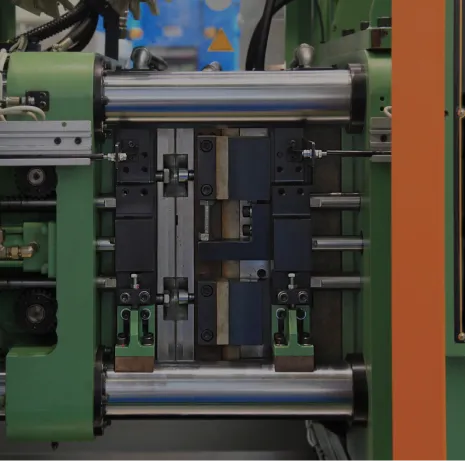

INJECTION MOULDS

- Manufacturing Feasibility check and design iterations.

- DFM | Mold Flow Analysis & Part Design Iterations.

- Detailed Tool Design and Sign off considering Molding infrastructure.

- Steel Cut Tooling to T-0Product | Part validation through Dimensional | visual parameters.

- Mould Buy off

6

SHIPMENT & INSTALLATION

- Tool Shipments & Clearance.

Tool Verification and clearance. - Commissioning on the selected machines.

- PPAP run and approvals.

- Project Sign off